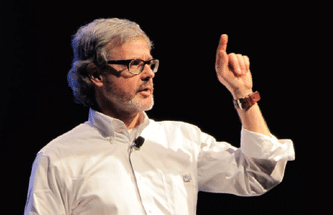

In this session, Mike Rother will discuss the research findings behind the books, Toyota Kata, the Toyota Kata Practice Guide, and Toyota Kata Culture. Developing new ways of thinking means practicing targeted behaviors daily. Practicing Improvement Kata/Coaching Kata (IK/CK) is a way of developing scientific skills and mindset, for achieving challenging goals, that gets integrated into the normal daily operation of a team or organization. Kata are structured routines that you practice deliberately, especially at the beginning, so their pattern becomes a habit and leaves you with new skills that you can build on.

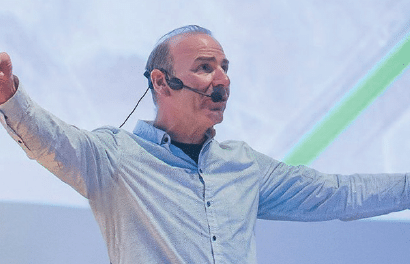

Companies have used the phrase, “people are our greatest asset,” for too long, and it is only partially correct. The truly engaged and talented people are the real asset of your company. Real change – sustainable change – relies more on your empowered people. Billy Taylor is an evangelist for people inclusion processes in operational excellence. It all comes back to the challenge: Institutionalizing Operational Excellence through everyone in your organization. Successful culture change is driven by diversity and inclusion, “it’s not about the source of the idea, it’s about the quality of the solution”.

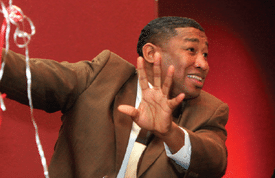

Paul Akers has taken his manufacturing business from the garage to worldwide distribution in 17 years by pursuing one goal —serve the customer by improving every day; with one ground rule—keep Lean simple. FastCap, with a product catalog of over 600 woodworking tools, now has 2,400 distributors in 40 countries. Paul credits the astounding business growth to a fun, dynamic culture in which each of the employees puts into practice at least one two-second improvement per day. He developed the culture by hiring the right people, relentlessly teaching and reinforcing the eight wastes, and empowering people to experiment. His lessons aren’t all orthodox, but he swears by them and so do many other businesses. Come here Paul speak and learn 2-Second Lean, you will be shocked how simple and fun it really is!

Jim Lancaster is the CEO of Lantech and Shingo prize-winning author of the Work of Management. Lantech was one of the first companies outside of Toyota and its suppliers to truly embrace the principles of the Toyota Production System. For years it enjoyed success after success as it converted operations from batch to flow production. In this candid presentation, Jim will share lessons learned and vividly describe the rise, fall, and rise again of Lantech’s continuous improvement effort.